ServicesServices

CLEANING & REPAIR

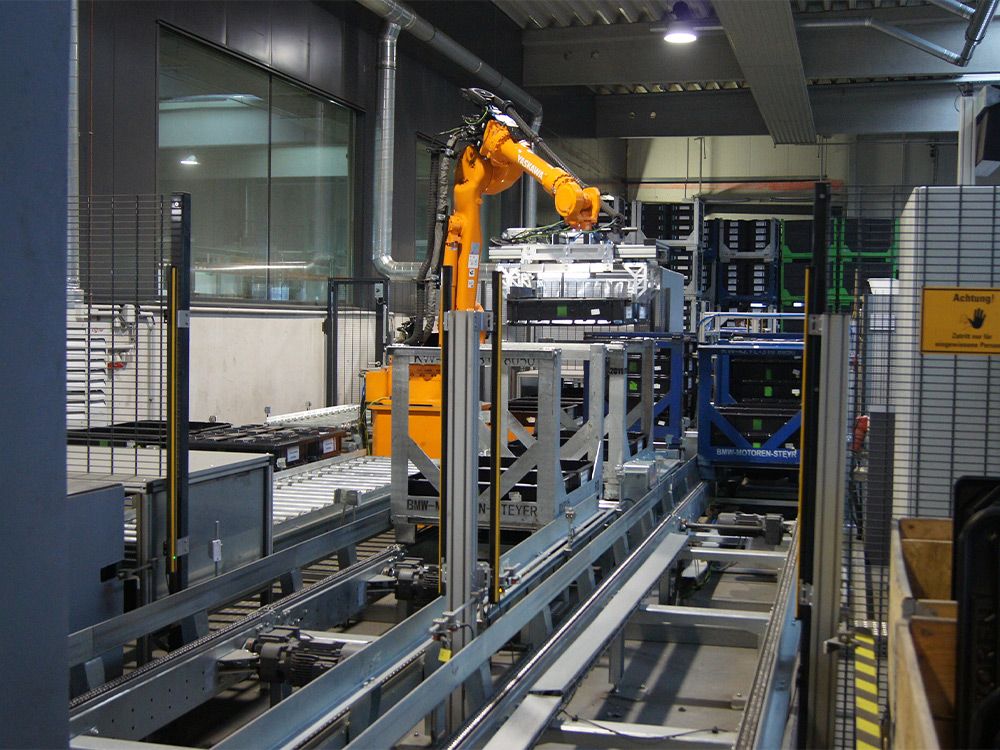

AUTOMATED CLEANING PROCESSES

container-specific solutions, tailored to your individual requirements

PROCESS SAFETY & 100% CONTROL

highest quality and efficiency through guided processes with daily traceability down to employee level

INTERNAL REPAIR CENTRE

repair of own and third-party containers: straightening work, welding of steel and plastic, components replacement

USE OF INNOVATIVE TECHNOLOGIES

platform connections for optimum track-and-trace time management and processing with our customers

HIGH COST EFFICIENCY

best possible use of resources through process optimisation and extension of service life by revitalising your containers

CLEANING METHODS

DRY ICE CLEANING

innovative method for abrasive-free surface cleaning without residual moisture

AIR JET CLEANING

effective cleaning with ionised air – dirt is whirled up and extracted – prevention of recontamination

VIBRATION TECHNOLOGY

oscillating cleaning process – to clean even hard-to-reach areas

BRUSHES

mechanical cleaning with brushes – ideal for stubborn dirt

WIPING

gentle manual cleaning with simultaneous quality control – for sensitive surfaces

repair centre

straightening work, steel and plastic welding, replacing broken parts, special cleaning

Transport simulation

We have the option of carrying out transport simulations and packaging tests tailored to your requirements. This checks whether your packaging meets the requirements to protect your product from damage.

YOUR ADVANTAGES

-

CLEAN PROCESSINg

-

REVOLUTIONIZING BLASTING PROCESS

-

TAILORED TO YOUR REQUIREMENTS

-

TRANSPORT SIMULATIONS

-

FAIR PRICES